ACID RESISTANT BRICKS

Engineered for exceptional durability and resistance to acids, our bricks are the ultimate choice for chemical plants, power stations, and more.

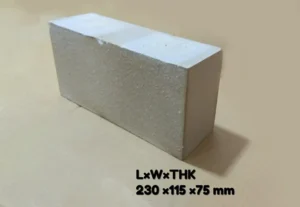

ACID RESISTANT BRICKS

Chemiprotect Engineers offer premium-grade unglazed clay bricks that are resistant to both acids and alkalis, conforming to Class-I of IS-4860 and ASTM C-279 Type II standards. These bricks are specifically designed for applications involving acid/alkali resistant linings, providing exceptional protection in highly corrosive environments.

Dimensions

| Color | Off White |

| Normal Standard Size | 25mm, 38mm, 65mm & 75mm |

| Normal Standard Thickness | 25mm, 38mm, 65mm & 75mm |

| Slip Resistance | Excellent |

| Standard Coverage Per M2 | 38 Pics |

Different size, thickness and colors available up on special request and for project orders

PHYSICAL PROPERTIES

| Class – 1 | Class - 2 | |

|---|---|---|

| Bulk Density (Approx.) | 2.2 to 2.3 g/cc | 2.2 to 2.3 g/cc |

| Normal Standard Thickness | 12, 15 & 20mm | 12, 15 & 20mm |

| Compressive Strength kg/cm2 Min | 700 | 500 |

| Water Absorption % Max. | 2 | 4 |

| Flexural Strength kg/cm2 Min | 100 | 70 |

| Resistance To Acid | Loss in wt. shall not exceed 1.5% | Loss in wt. shall not exceed 4% |

ANALYSIS

| SiO2 | 70 to 72% |

| Al2O3 | 21 to 24% |

| Fe2O3 | 1.2% |

| K2) + Na2) | 2 to 3% |

DESIGN VIEW FOR ACID RESISTANT BRICK/TILE LINING THE MEMBRANE BRICK/TILE/STONE LINING

- ACID RESISTANT TILE/BRICK/STONE

- ACID/ALKALI RESISTANT BEDDING & JOINTING MORTAR

- IMPERVIOUS INTER-LINER ANTI-CORROSIVE PRIMER

- CONCRETE SURFACE

DESIGN VIEW FOR ACID RESISTANT BRICK/TILE LINING THE DIRECT BOND

- ACID RESISTANT TILE/BRICK/STONE ACID/ALKALI RESISTANT BEDDING & JOINTING MORTAR

- ANTI-CORROSIVE PRIMER

- CONCRETE SURFACE